Defective 5th wheels on yellow dollies.

Lately I've been hearing of a bunch of dropped trailers around the company because of these Holland brand 5th wheels coming uncoupled after the driver has driven sometimes 100's of miles.

Recently I heard down in Cincinnati that a driver has been fired for dropping one after the garage had determined that there was a problem (defect) with this unit.

Can anyone else share their information on here about anyone else going through this & how to protect his or her job. What to look for, problem signs.

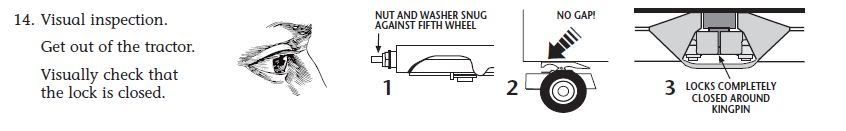

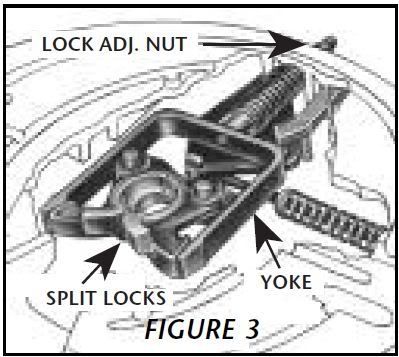

I've asked many different mechanics & received many conflicting instructions on what to look for. Especially concerning the adjustment bolt sticking out the front.

Lately I've been hearing of a bunch of dropped trailers around the company because of these Holland brand 5th wheels coming uncoupled after the driver has driven sometimes 100's of miles.

Recently I heard down in Cincinnati that a driver has been fired for dropping one after the garage had determined that there was a problem (defect) with this unit.

Can anyone else share their information on here about anyone else going through this & how to protect his or her job. What to look for, problem signs.

I've asked many different mechanics & received many conflicting instructions on what to look for. Especially concerning the adjustment bolt sticking out the front.

, YRC trailers that have the blue lettering. Especially, when drivers refuse to apply grease on the 5th wheel. Because, it does is wear and tear the kingpin head, shaft, and the kingpin apron underneath the trailer.

, YRC trailers that have the blue lettering. Especially, when drivers refuse to apply grease on the 5th wheel. Because, it does is wear and tear the kingpin head, shaft, and the kingpin apron underneath the trailer.